Thor stake drivers are indispensable tools for various landscaping and construction projects, known for their power and efficiency. However, their robust construction doesn't negate the need for regular maintenance. Consistent use subjects these powerful machines to significant wear and tear, impacting performance and potentially leading to costly repairs or premature failure. Neglecting maintenance can not only reduce the lifespan of your stake driver but also compromise the safety of yourself and those working around you. Proper care ensures optimal performance and extends the useful life of this valuable investment.

This guide will provide a comprehensive step-by-step process for maintaining your Thor stake driver, covering essential checks and cleaning procedures. By following these simple yet effective maintenance steps, you can significantly extend the life of your tool and ensure it continues to deliver reliable performance for years to come.

Preparation and Safety Guidelines

- Thor Stake Driver (Honda 4-stroke and 2-stroke models)

- Always disconnect the power source before performing any maintenance or cleaning. Failure to do so could result in serious injury or death.

- Wear appropriate safety gear, including eye protection and gloves, when handling the stake driver and its components. Sharp edges and moving parts present significant risks.

- Never attempt repairs beyond basic maintenance (lubrication, cleaning). Consult a qualified technician for any major repairs or damage to avoid further damage or potential injury.

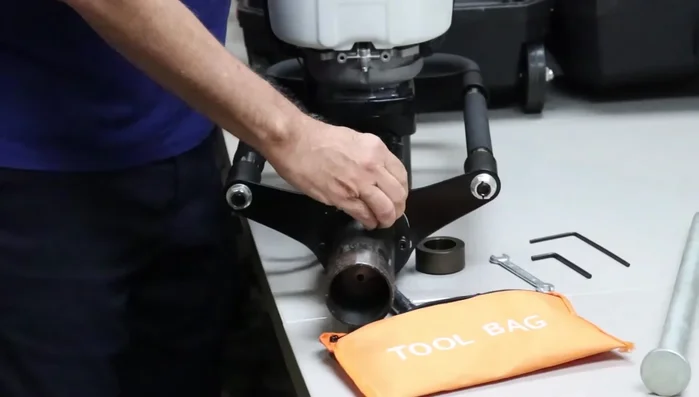

Step-by-Step Instructions

Initial Setup

- After initial setup, drive a few stakes to ensure the impact plate is properly seated. This prevents it from falling out during operation.

Fuel System Maintenance

- At the end of the season, run the unit until it's completely out of gas to clear the carburetor and fuel tank. Use fresh fuel every time you restart the unit.

Four-Stroke Engine Maintenance

- Change the oil in the crankcase every 10-15 hours of use or after a week or two of heavy use. This helps remove any metal filings and ensures smooth operation.

- Check and refill the upper crankcase with SAE 90 gear weight oil regularly.

Four-Stroke Engine Maintenance Regular Weekly Maintenance

- Check and tighten the hex cap screws on the bottom of the unit weekly to prevent oil leaks.

- Regularly inspect and tighten all Phillips head screws and other fasteners on the unit, particularly those on the throttle and casing.

Regular Weekly Maintenance

Read more: Ultimate Guide to Tarp & Tent Staking: Secure Your Shelter in Any Condition

Tips

- Use synthetic oil for two-cycle engines. A pre-mixed synthetic option is recommended for ease of use.

- Always use fresh fuel, especially after storage periods. Old fuel can damage the engine.

- The tool kit included with the unit contains all the necessary wrenches for maintenance.

- Regular maintenance (weekly or monthly) is crucial to extend the life of the stake driver.

- Always drive stakes straight up and down for optimal driving strength.